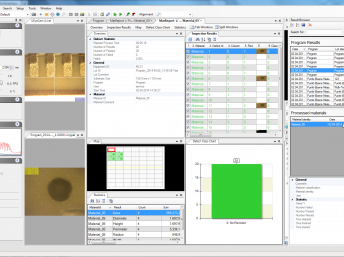

Macro Inspection

Macro inspection and documentation: The wafer handling system is equipped with different selectable light sources. On the one hand with a homogeneous light field plate for bright field inspection and on the other hand with a dark field light source for the inspection for particles, scratches etc.

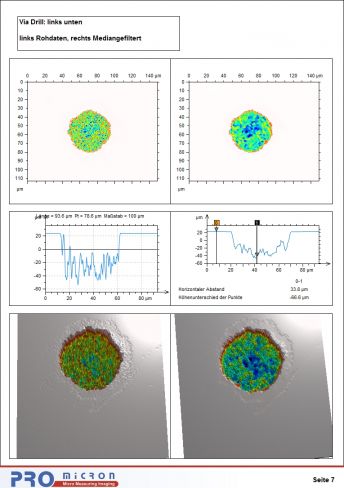

3D Bond Control

Testing of wedgebonds and ballbonds with 3D microscopy.

White light interferometrie and confocal microscopy in conjunction with special software modules.

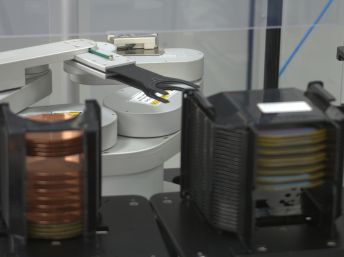

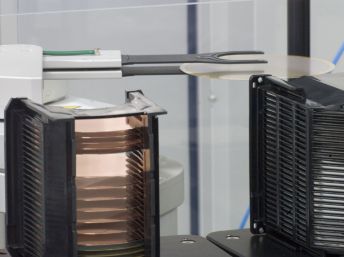

Wafer Handling

Robots and prealigner according to the requirements and eligible accessories for:

- Vacuum backside handling

- Vacuum edge handling

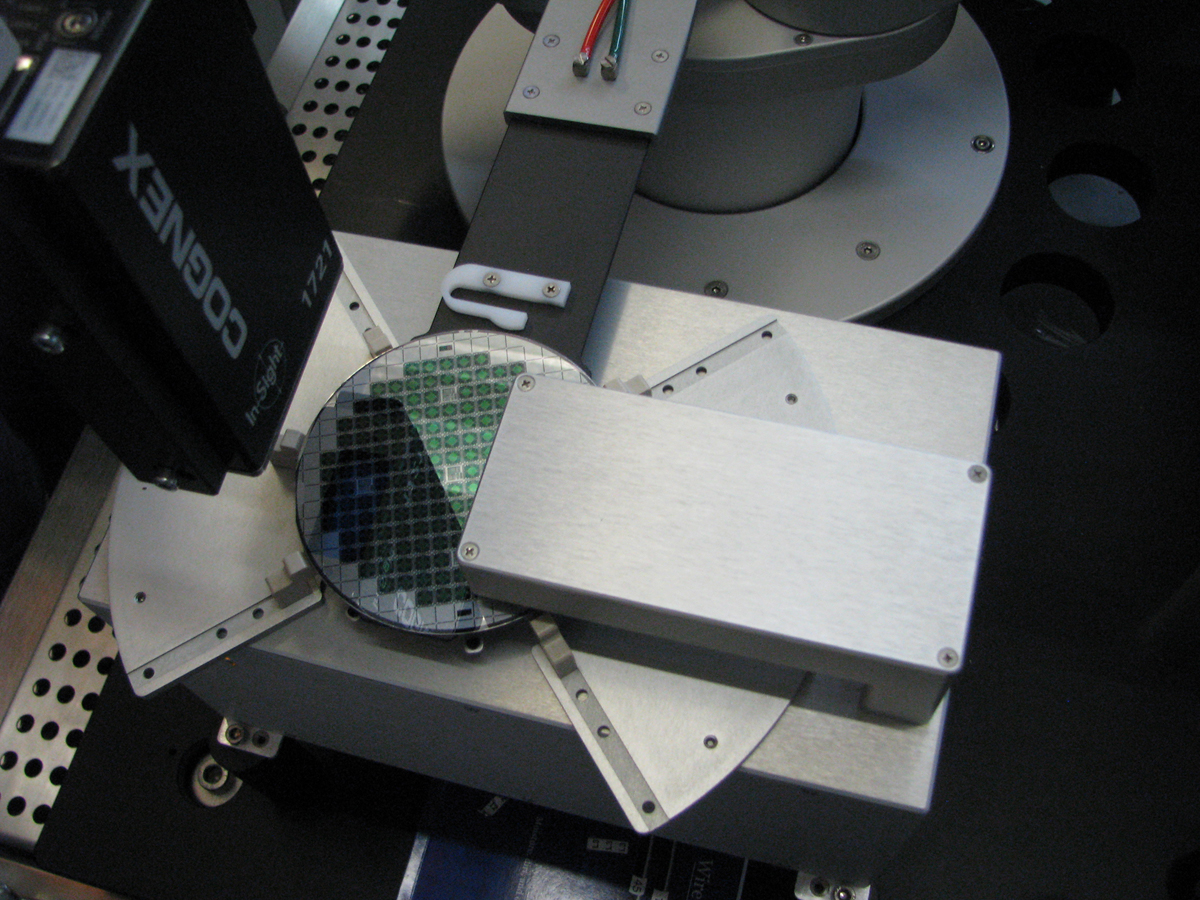

Vacuum Gripping Technology

To solve various measurement and inspection tasks, Promicron relies on a large number of optical methods. They are combined according to requirements and customer request.

Edge Gripping

An edge gripper takes up a substrate (such as a wafer) and releases it again. To solve various measurement and inspection tasks, Promicron relies on a large number of optical methods. They are combined acoording to requirements and customer request.

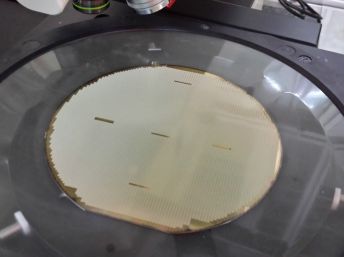

Bonded Wafers

Bonded wafers are considerably thicker than single wafers and can have an offset. They may be non-circular. To solve various measurement and inspection tasks, Promicron relies on a large number of optical methods. They are combined acoording to requirements and customer request.

Bow & Warp Wafer

Promicron offers proven solutions for safe wafer handling, even for those with clear bow/ warp, to ensure a safe handling.

By using corresponding soft- and hardware modules, the measurement and graphic representation of the wafer bow / warp is possible as well.

Wafer Chuck

Promicron uses various methods (e.g. friction or vacuum) and adapts them according to the given requirements and the customer' request.

Wafer on Tape

Vakuum Chucks with a finest porous surface for sawn wafers on blue tape. Even wafers with minute dies are sucked in safe and even.

Wafer Dicing Inspection

Inspection and metrological control of the sawing lines on:

- Missmatch or alignment error

- Saw depth

- Chipping

QR Code Reading

QR codes and barcodes or plain text can be read automatically through external adapted reading devices (code reader) or possibly in the camera image of the microscope.

Mask Inspection

Inspection of masks used to produce wafers.

The task of the inspektion is to detect random errors (scratches, particles) and systematic / structural faults.

Chrome on glass substrates are usually inspected in transmitted light - incident light and dark field can also be used.

Within the scope of the measurement, quality parameters of existing masks (e.g. abrasion) can also be checked.